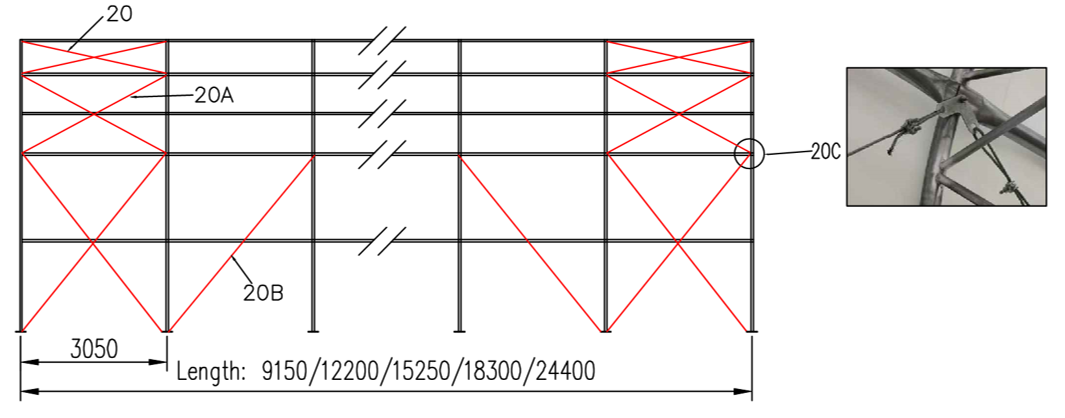

Model GS30 (30,40,50,60,70,80) 20

Size: W 9.15 x L 9.15 (12.20, 15.25, 18.30, 21.35, 24.40) x H 6.1 m

Maximum wind load 80 km/h

The maximum snow load is 0.28 kPa

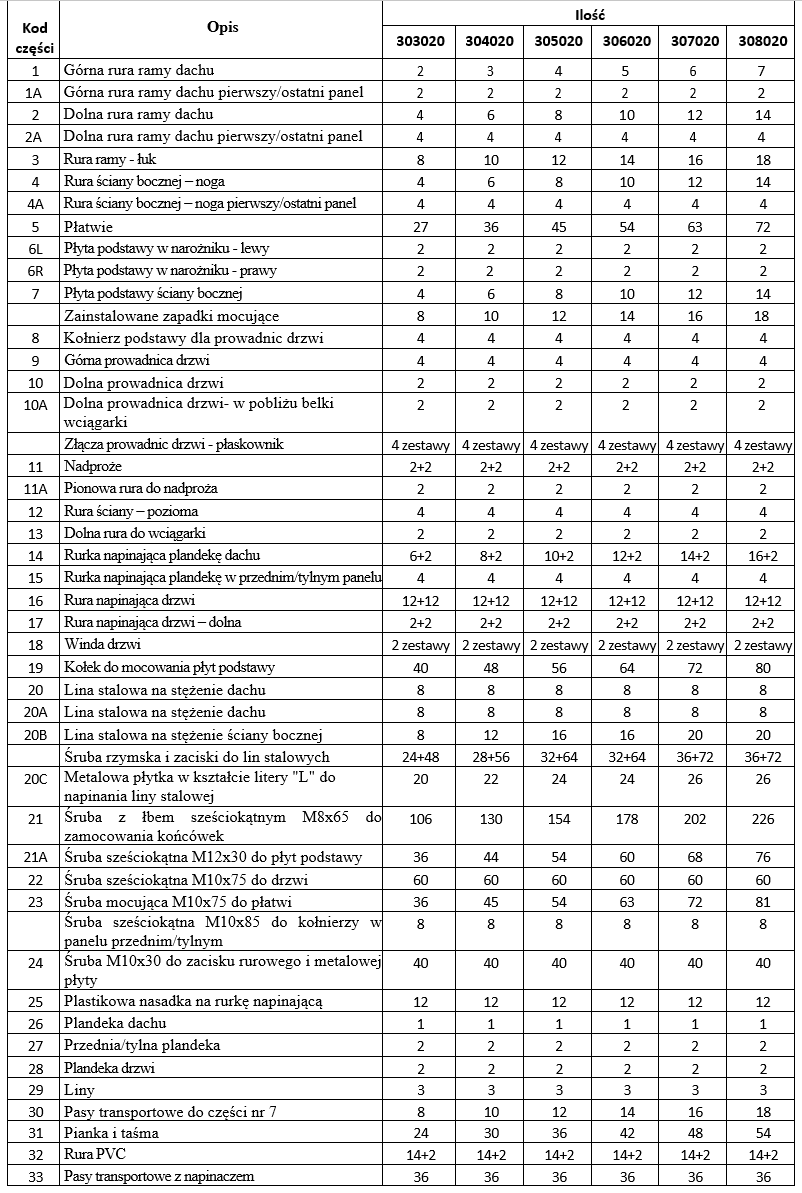

LIST OF PARTS

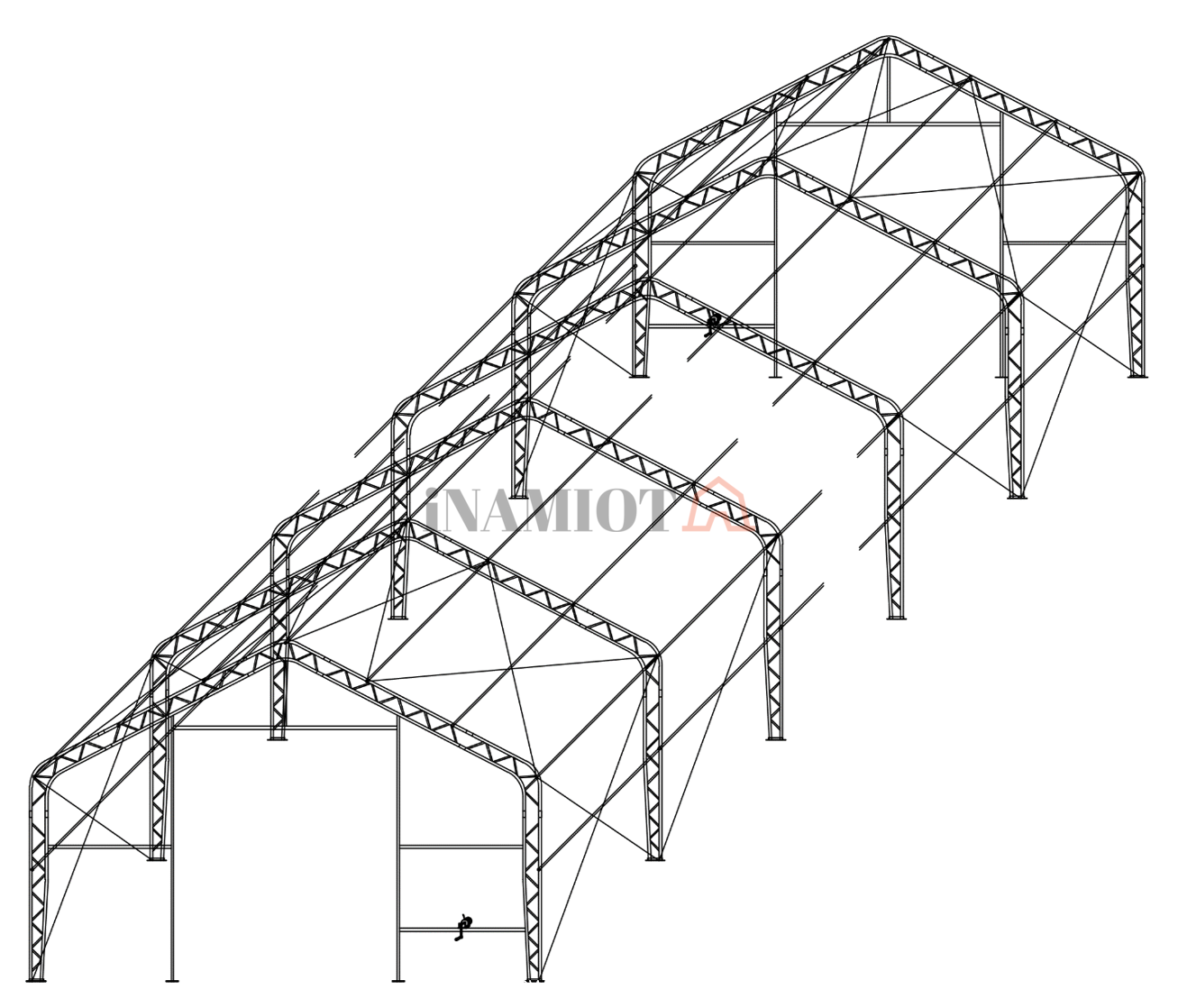

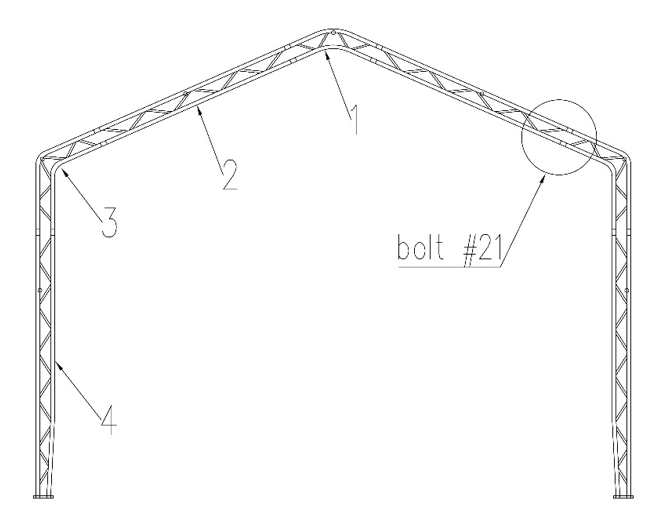

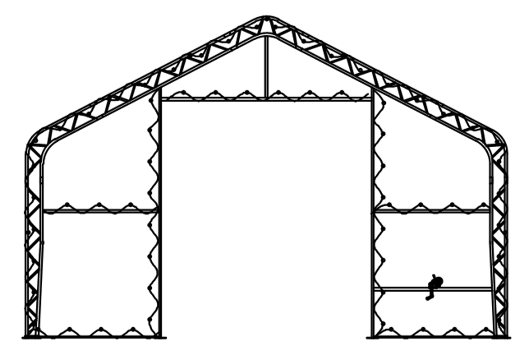

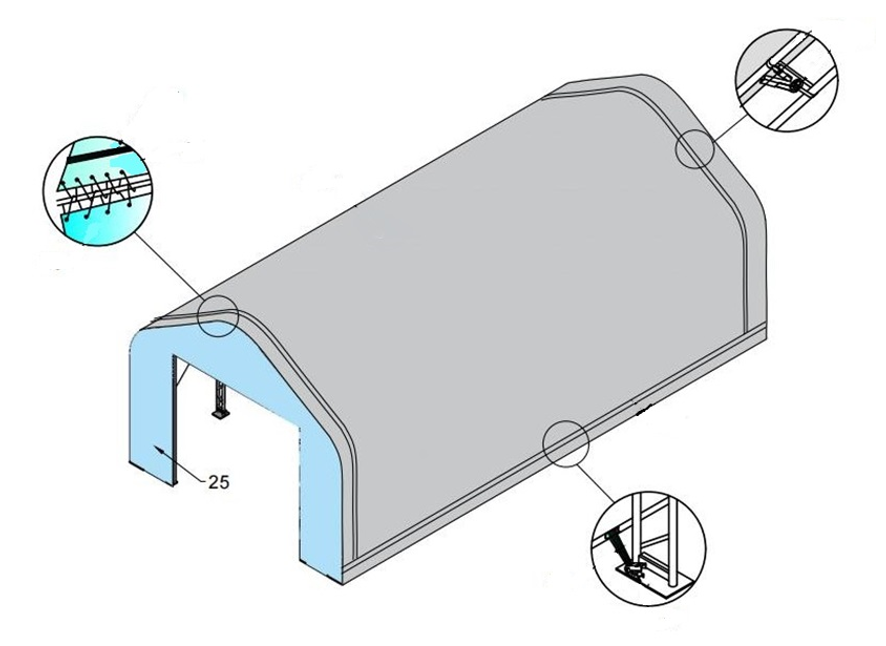

Fig. 1 Structure of the marquee hall.

IMPORTANT----- FIRST READ THE INSTRUCTIONS

Improper site preparation, erection and maintenance may invalidate the warranty and result in an unnecessary and costly error. If you have any questions, please contact us tel. +48604108143 email: kontakt@inamiot.pl

For easy assembly, we have identified each individual component with the part code indicated in the parts list. Familiarise yourself with the part code numbers and the drawing to ensure trouble-free assembly.

Video - assembly instructions for the marquee hall.

1. Check the contents of the shipment after opening the transport box. Make sure all tent hall components are in the crate.

2. Do not set up the festival marquee in strong winds, in marshy areas or on unstable ground. Check the weather forecast.

3. The marquee hall should be erected on a firm level base. The tolerance for deviations in dimensions is +/- 1 cm. It is recommended to make concrete pours for the mounting columns with dimensions of 50x50x80 cm with a reinforcement rod fi 10 mm 4x10 mm stirrup fi 6 every 20. It is not allowed to base the object directly on unconsolidated and unstabilised ground, on loosened and loose soil with compaction indices below Id<0.6.

4. Ground anchors should be driven full length into the ground in such a way that they cannot be accidentally pulled out. Anchors should be driven into the ground at an angle.

5. Check local regulations and plan the installation site so that the required distance from electrical, gas, water and other cables is maintained.

6. Pay attention to the direction of the screw. Do not install the bolts on top of the structural frame of the tent where the fabric will rest, as you will damage the fabric.

7. Cover all pipe joints with repair tape (silver tape) to secure the canopy. Cover all wire rope ends with repair tape (silver tape) to secure the canopy. Use the shims provided between the tent structure and the canopy.

8. Work in accordance with health and safety requirements. Take care not to cut your fingers with clamps and tubes during assembly. Assemble with protective gloves, work boots etc.

9. Ensure that you have access to the marquee hall from all sides during assembly, so that you can manoeuvre with a forklift, telescopic loader, hoist etc .

10. All work should be carried out by professionally qualified persons.

11. Keep the work area clean.

12. Do not use sharp tools when in contact with the tarpaulin.

13. If you are installing the curtain in winter, the curtain itself must be stored in a room with a minimum temperature of + 10 C or higher 2 days before installation. must be unfolded at this temperature. Otherwise cracks or fractures may appear in the curtain.

14. The marquee may only be assembled from the components supplied. It is not permitted to alter the components of the marquee hall. It is not permitted to alter, change etc. the components of the marquee hall. Any changes to the components, substitutions of components will void the guarantee.

15. Snow must be removed immediately. Accumulating snow may cause excessive strain on the structure and result in damage.

16. No additional loads may be attached to the tent structure. The structure is only rated for snow load, wind load and its own weight.

17. The lower parts of the tarpaulin, below the tarpaulin tension tube, must remain loose. They must not be pressed down or fixed permanently, as this is where air pressure escapes from the tent in the event of gusts of wind.

EQUIPMENT AND TOOLS NEEDED FOR INSTALLATION

1. Measuring tape

2. Repair tape (silver tape)

3. Chalk(marker)

4. spirit level

5. Screw spanners.

6. Step ladder

7. Hammer

8. Knife, scissors

9. Power tools

INSTALLATION PROCESS

INSTALLATION OF BASE PLATES

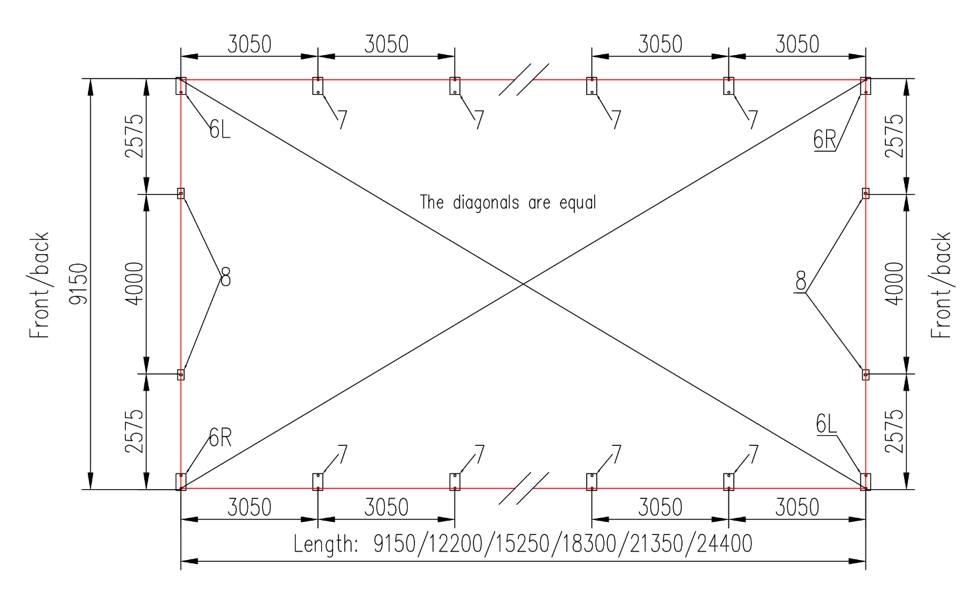

Fig. 2 Location of the base plates.

1. Please refer to the drawing to position the base plates (number 7, 6L, 6R). Number 8 plates are installed later . Measurements are given from centre to centre of the base plates.

The fixing pins on the side wall base plates are close to the outer pipe, not the inner pipe. Fix the base plates using dowels part no. 19.

Make sure that the base plates are installed parallel to each other and at right angles to the opposite base plates.

When installing on the ground, fix the base plates with the dowels provided in the kit. The pegs are driven at an angle to the ground.

When installing the storage marquee on paved ground, use the pegs. The pegs should be adapted to the ground on which the tent is mounted.

FRAME INSTALLATION

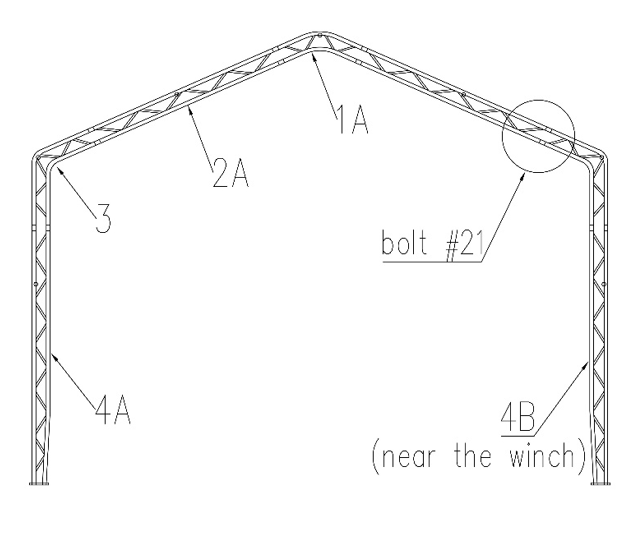

2. Assembly of front and rear frame .

- 1 pcs upper roof frame tube (nr. 1A),

- 2 pcs lower roof frame tube (nr. 2A),

- 2 pcs frame tube - arch, (nr. 3),

- 2 pcs side wall tube - leg (nr. 4A),

- ScrewsM8*55 mm (nr. 21 ) .

3. Mount the first arch as shown in the picture below. Connect the components listed above with screws (no. 21). Set the assembled tent frame element into the base plates. Connect each group of arches using hexagon-head bolts with washers and nuts through the pre-drilled holes in the frame. Do not fully tighten the nuts until the entire frame is fully assembled and seated in place.

Fig. Front and rear frame assembly.

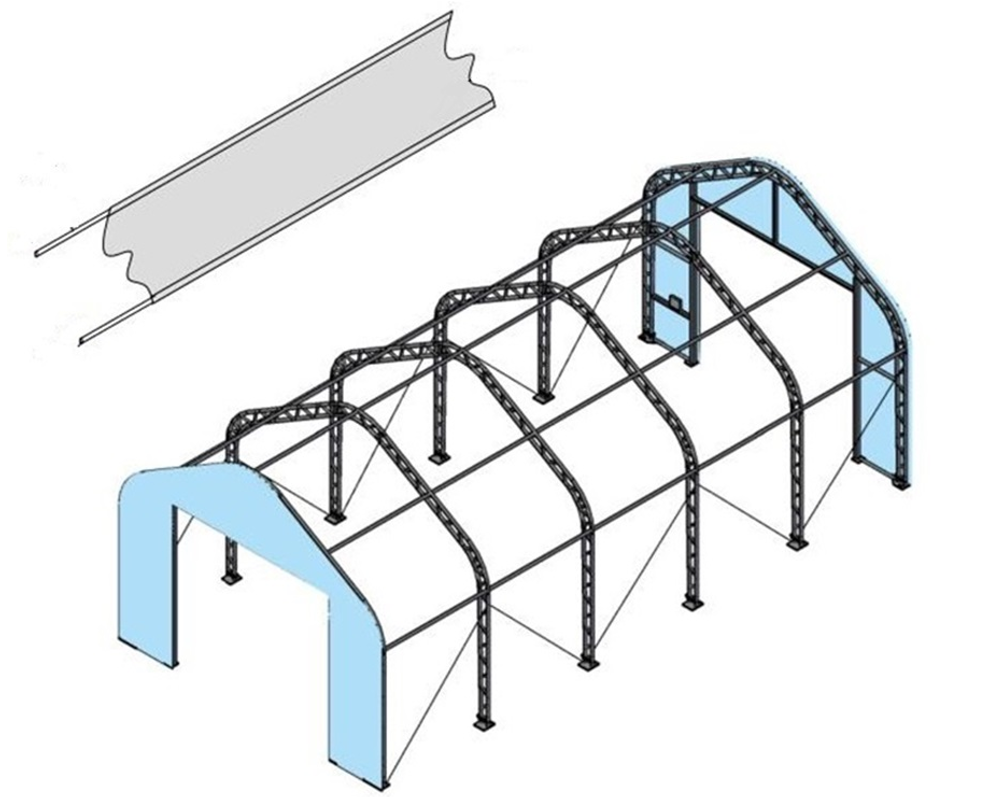

4. Centre frame assembly.

- 1 pcs upper roof frame tube (no. 1),

- 2 pcs lower roof frame tube (no. 2),

- 2 pcs frame tube - arch, (no. 3),

- 2 pcs side wall tube - leg (no. 4),

- M8*55 mm bolts (no. 21 ) .

Twist the middle arches in the same way as the first arch.

Note: The sections of the front and rear arches are different from the centre arches.

Fig. 4 Assembly of the centre frame.

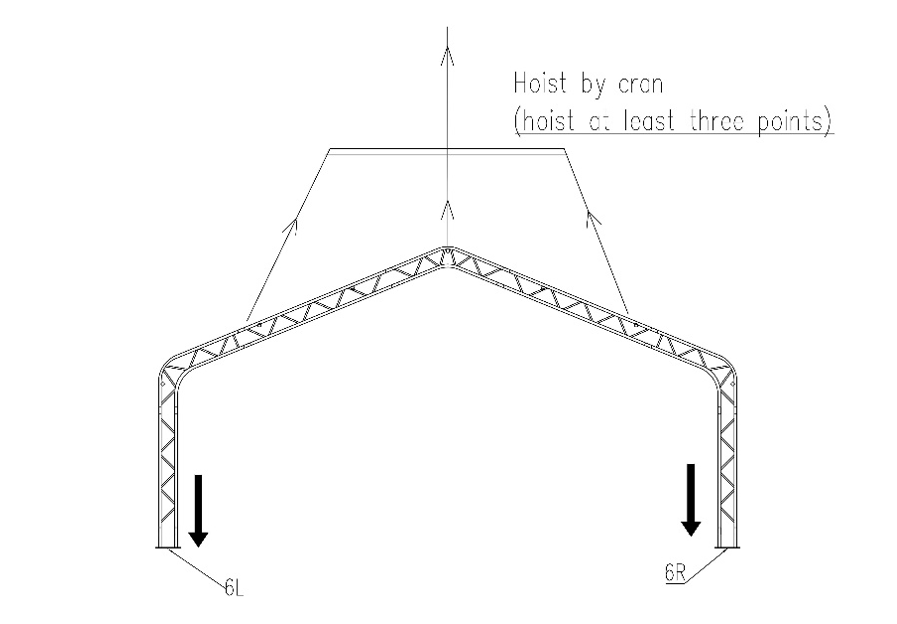

5. Assembly of the first front and second arches. Slowly lift the first arch with a crane (lift at least three points). Place the first/front arch on the corner base plates #6L and #6R. Connect with screws. At the same time, support the arch with ropes, crane, etc. to make sure the arch stands stable. Once the front arch has been erected, erect the first inner arch in the same way. Note: attention must be paid to stability during this process.

Fig. 5 Raising the first arch

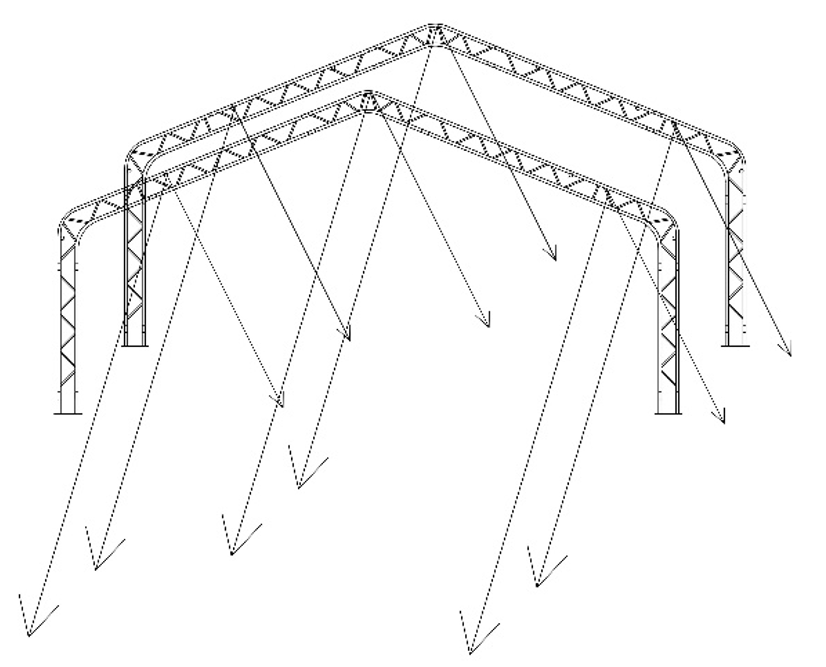

6. Connect the first two arch groups using purlins (no. 5) and M8x65 screws (no. 23) .

Fig. 6 Lifting of subsequent arches

7. Install the wire rope roof bracing (No. 20/20A) and sidewall No. 20B according to the drawing below. Use the "L" flat bar (No. 20C) to tension the wire rope. Once all the bracing cables have been installed, the turnbuckles should be lightly tightened to adjust the arches vertically and increase their rigidity.

Fig. 7 Installation of roof and side wall bracing.

8. Wrap the joints of the arches with repair tape (silver tape).

Fig. 8 Securing the joints of the arches with repair tape.

ASSEMBLY OF FRONT AND REAR WALL

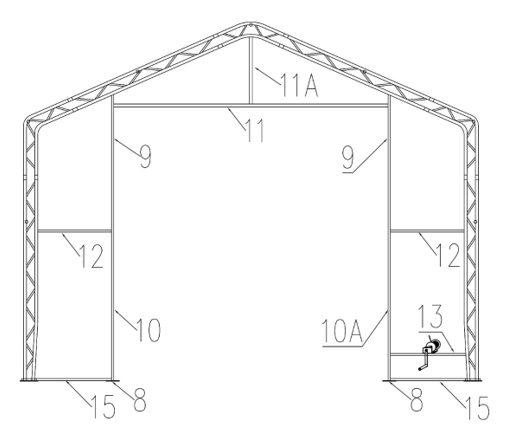

Fig. 9 Assembly of the front and rear wall.

9. Assembly of front and rear wall frame.

- Assemble the door guide 9, 10 (or 10A)

- Assemble the door lintel part no. 11 and the vertical tube for lintel no.11A

- Assemble the horizontal wall tube (no. 12)

- Assemble the winch beam (no. 13)

- Connect to the base plates (no. 8)

- Fix the base plates with dowels

- Assemble the tension tube (no. 15)

Remember to wrap all pipe joints with repair tape (silver tape). Finally, install the front and rear wall braces.

Fig. 10 Installation of the remaining braces.

After installing all the steel cables (20B), tighten the turnbuckles slightly to adjust the arches vertically and increase rigidity.

CHECK the entire frame structure for squareness and verticality, adjust tubes and bolts if necessary. Then tighten the frame bolts accordingly. DO NOT over-tighten the bolts so that the oval parts of the frame are not compressed.

The last thing to do in this step is to wrap tape around the joints of the bow sections and other necessary places where parts may rub against the tarpaulin.

ASSEMBLING THE TARPAULIN

10. Once you have assembled the front and rear walls, you can assemble the front and rear tarpaulins using a rope ( no. 29) to be pulled through the eyelets in the tarpaulin. Take care to tie the tarpaulin evenly and firmly.

Fig. 11 Assembly of front and rear tarpaulins.

11. For the installation of the roof tarpaulin you need a couple of people and a hoist, e.g. a telescopic hoist. Remember that if you are fitting the tarpaulin in the winter, it should warm up before fitting at a minimum temp. 10C. Do not install the curtain on the frame in strong wind conditions. Before tensioning the curtain, check that the pipe joints are well taped with repair tape (silver tape).

Fig. 12 Structure with mounted curtains.

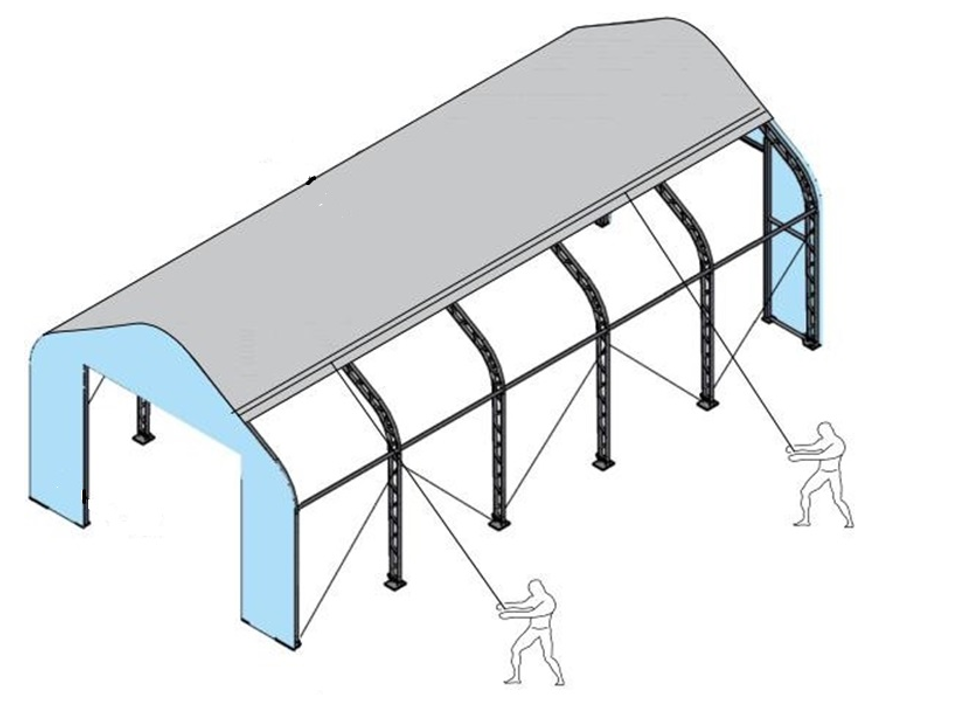

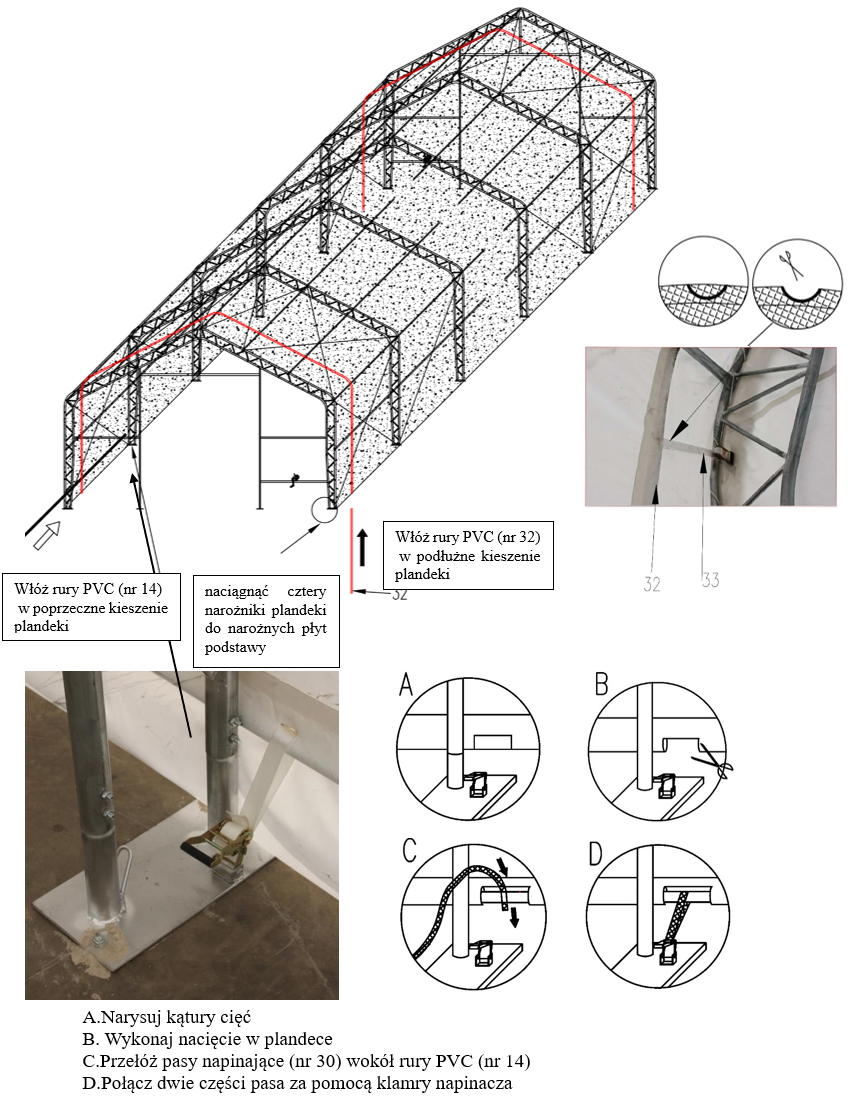

12. Unfold the roof tarpaulin on one side of the tent. Insert the steel tubes (14) into the pockets of the tarpaulin. Cut small holes in the pockets with the pipes and tie the ropes at this point. Make cuts every 3 m or so. Position one person to one rope. Throw the rope over the tent frame and pull the tarpaulin over the tent frame.

NOTE: pull the tarpaulin over the frame evenly, carefully and slowly. One person should be inside and watch that the tarpaulin does not catch on the tent structure. If necessary, lift the tarpaulin. After pulling the tarpaulin, tie it to the structure at the corners. Align the tarpaulin back and forth and sideways on the structure.

Fig. 13 Stretching the curtain

13. Fit the PVC pipes in the pockets at the front and back of the tarpaulin. Align the tarpaulin front/rear, then left/right. Stretch the tarpaulin front/rear. Pull the tarpaulin left/right.

Fig. 14 View of the tensioned tarpaulin.

Fig. 15 Tensioning the tarpaulin

14. Use the transport straps to tension the tarpaulin as shown above. Be careful, there are a couple of different models of belt tensioners and straps included for different parts of the tent hall.

15. Put the plastic cover over the ends of the tensioning tube.

DOOR ASSEMBLY

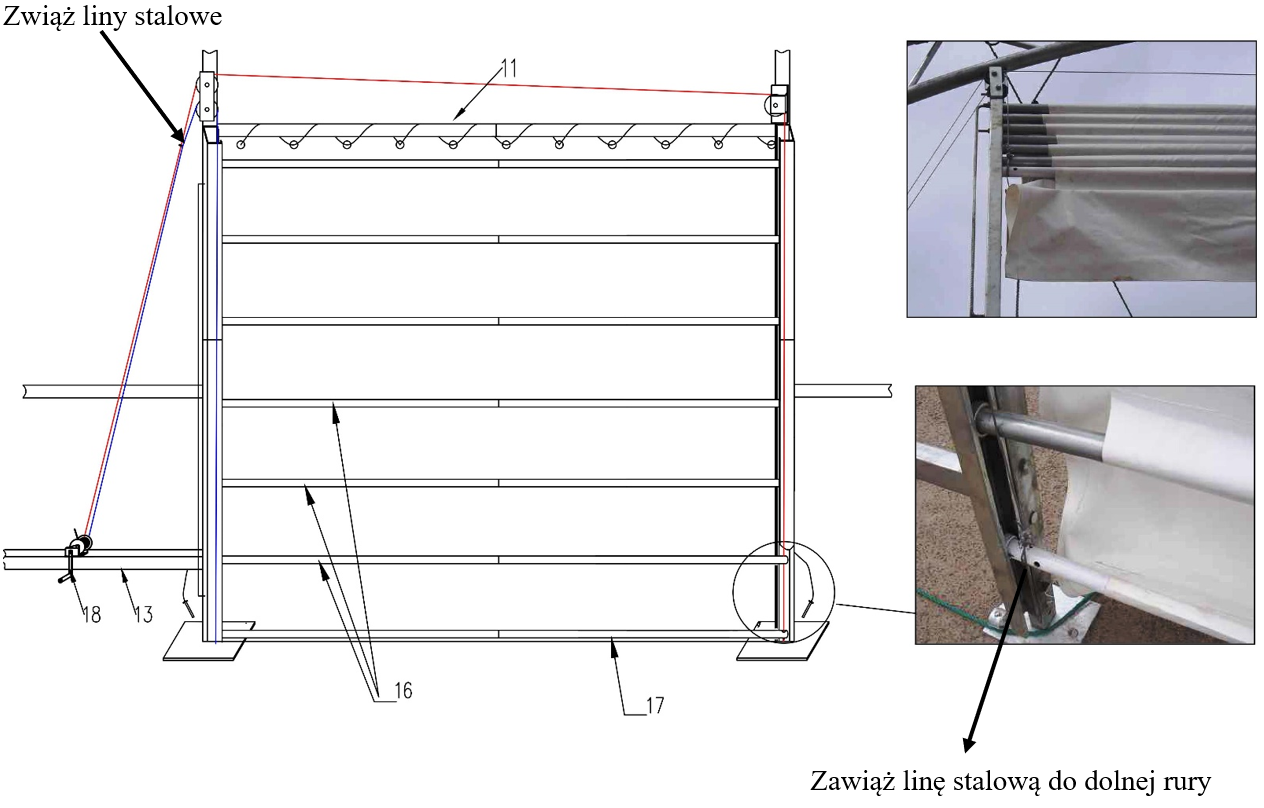

16. Fit the winch mechanism (no. 18) to the lower beam of the front panel (no. 13)

17. Slidethe tension tubes of the door material (parts No. 17and No. 16) into the door pocket .

18. From the bottom side of the door guides, gently lift the door cover and slide the door drop tubes into the door guides

19. Fit the two steel guide cables from the door winch.

- Shorter steel cable: pass through the lower pulley of the double pulley at the top of the door guide and down into the hole in the lower door tension tube, then tie a knot.

- Longer wire rope: go through the top pulley of the double pulley at the top of the door track, go through the single pulley on the other door track and then go down to the hole in the lower door drop tube and tie a knot.

20. The door can now be opened or closed using the winch assembly. Raise and lower the door a few times to ensure that the ends of the door tubes do not lock onto the track. If necessary, lubricate them.

Fig. 16 Installing the door.

CAUTION: DO NOT leave the roof covering unattached in any circumstance until final assembly and tightening is complete.

The process is fairly easy. But some tightening adjustments will be necessary to get a flat, taut roof tarp. Please inspect the roof covering at least once a month.

Operation guide.

1. When using, make sure there is adequate ventilation for fumes and other hazardous fumes .

2. Be aware of energy and heat sources. Do not keep heat sources near the tarp. Do not expose to open flames.

3. Heating appliances and other heat sources, must be min. 2 m from the canopy.